Are you worried about keeping fluids completely clean in your system?

In many industries, even the smallest bit of contamination can cause big trouble.

Whether it’s in pharmaceuticals, food processing, or electronics manufacturing, the fluid flowing through the system must stay pure from start to finish. That’s where high-purity valves come in.

These valves are designed to protect the flow and keep everything as clean as possible while still handling pressure, flow changes, and constant use.

Contents

Table of Contents

ToggleWhat Makes a Valve High-Purity?

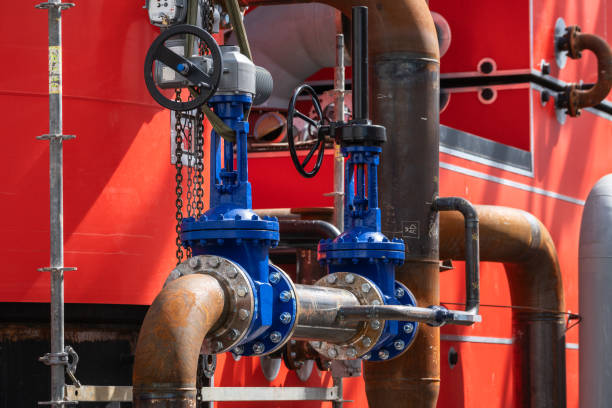

A high-purity valve is made to keep the inside flow path smooth, clean, and free from anything that could affect the quality of the fluid. It uses materials that don’t react with the fluid and a design that stops particles, bacteria, or air from getting in.

These valves are different from regular ones because they’re built with precision and cleanliness in mind. From the body material to the way the valve is sealed, every part is chosen to make sure the fluid stays pure.

Where These Valves Are Used

You’ll find high-purity valves in places like:

- Cleanroom environments

- Pharmaceutical production lines

- Beverage and food filling systems

- Water purification setups

- Semiconductor manufacturing

Material Choice Plays a Big Role

Materials used in these valves are carefully selected. Stainless steel, PVDF, or high-grade plastics are common.

These materials don’t rust, break down, or release particles into the fluid. This helps maintain the purity level that the process requires.

Also, the inner surface of the valve is often polished or treated to be extra smooth. This reduces the chance of anything sticking to the surface or building up over time.

Smooth Internal Design for Clean Flow

One of the key points in high-purity valve design is having no sharp corners or gaps inside the flow path. Fluid should be able to move through without turbulence or pockets where dirt or bacteria can hide.

This kind of smooth flow helps maintain stable quality and avoids problems like bacterial growth or fluid breakdown.

Cleaning and Sterilization Support

In critical systems, cleaning happens often. Valves must be able to handle regular sterilization using steam, hot water, or special cleaning solutions.

High-purity valves are built to go through these cycles without breaking down or losing their sealing strength.

Helping Maintain Consistent Product Quality

When a product depends on water, chemicals, or ingredients staying clean, the valve becomes a gatekeeper. If the valve allows contamination, the end product won’t meet quality checks. High-purity valves help keep everything under control by ensuring that nothing unwanted enters or mixes with the fluid.

They also help keep the flow stable, which matters a lot in systems where pressure and flow need to stay within a small range. Sudden changes can affect blending, filling, or chemical reactions.

Seal Design and Tight Shutoff

The sealing surface of a high-purity valve is another important feature. It must close tightly every time to avoid even tiny leaks. Any backflow or trapped fluid can lead to contamination in the next batch or cycle.

Using ball valves in some sections of high-purity systems helps achieve this clean shutoff. These valves offer full flow when open and strong sealing when closed, making them a simple and effective choice in many clean fluid setups.

Good Fit for Plastic-Based Systems

In many cleanroom or lab setups, plastic piping is used instead of metal. In these cases, PVC Ball Valves fit perfectly with the rest of the system.

They provide the same reliable shutoff and clean flow control while matching the chemical compatibility and non-reactive nature of the rest of the setup.

Less Downtime, Easier Maintenance

Since high-purity valves are built with clean operation in mind, they need less frequent maintenance. They don’t clog easily, and the smooth internal design makes cleaning fast.

Also, when it’s time to replace parts like seals or diaphragms, it can often be done without removing the entire valve from the line.

Supporting Regulatory Standards

Industries like pharma and food are highly regulated. Equipment, including valves, must meet standards for cleanliness and safety.

High-purity valves are often certified or tested to meet those standards, giving peace of mind to teams that handle sensitive materials.

Having the right valve also helps during inspections, as the documentation and design support the overall quality assurance efforts.

Reducing Waste and Product Loss

Every bit of contamination means wasted material. That could be in the form of rejected batches, flushed lines, or unscheduled cleaning.

High-purity valves reduce the chance of contamination, which also reduces how much waste a system produces.

Final Thoughts

In critical systems where purity is a top priority, valves play a bigger role than most people realize. They are not just switches for flow; they help protect the fluid, maintain product quality, and support clean, smooth operation.

Choosing valves that support clean flow and tight shutoff, like ball valves and PVC options, helps keep the system stable and reliable. And when every part works together, the result is a process that runs cleaner, faster, and more confidently.