Table of Contents

ToggleWhat Is a Vacuum Pump Used For

A vacuum pump is a versatile device that plays a crucial role in various industries and applications. So, what exactly is a vacuum pump used for? Well, its primary function is to create a vacuum or low-pressure environment by removing gas molecules from an enclosed space.

One common use of vacuum pumps is in industrial processes such as manufacturing and production. They are employed to remove unwanted gases or vapours from the system, ensuring the desired conditions for efficient operation. Vacuum pumps are also utilised in laboratories and research facilities for experiments that require controlled environments.

In addition to industrial and scientific applications, vacuum pumps have significant importance in everyday life. For instance, they are essential components of HVAC systems, helping to maintain proper air circulation and temperature control. Moreover, they play a vital role in medical equipment like suction devices used during surgeries or dental procedures.

Another interesting use of vacuum pumps can be found in culinary arts – yes, you read that right! Some chefs utilise these devices to infuse flavours into ingredients through the process known as vacuum marinating or sous vide cooking. By removing air from the food package using a vacuum pump, flavours penetrate deeper into the ingredients resulting in enhanced taste profiles.

So there you have it – an overview of what a vacuum pump is used for across different industries and disciplines. From maintaining product integrity during manufacturing to enabling cutting-edge scientific research, these machines play an integral role behind the scenes. Whether you’re aware of it or not, chances are you’ve benefited from their capabilities more times than you realise!

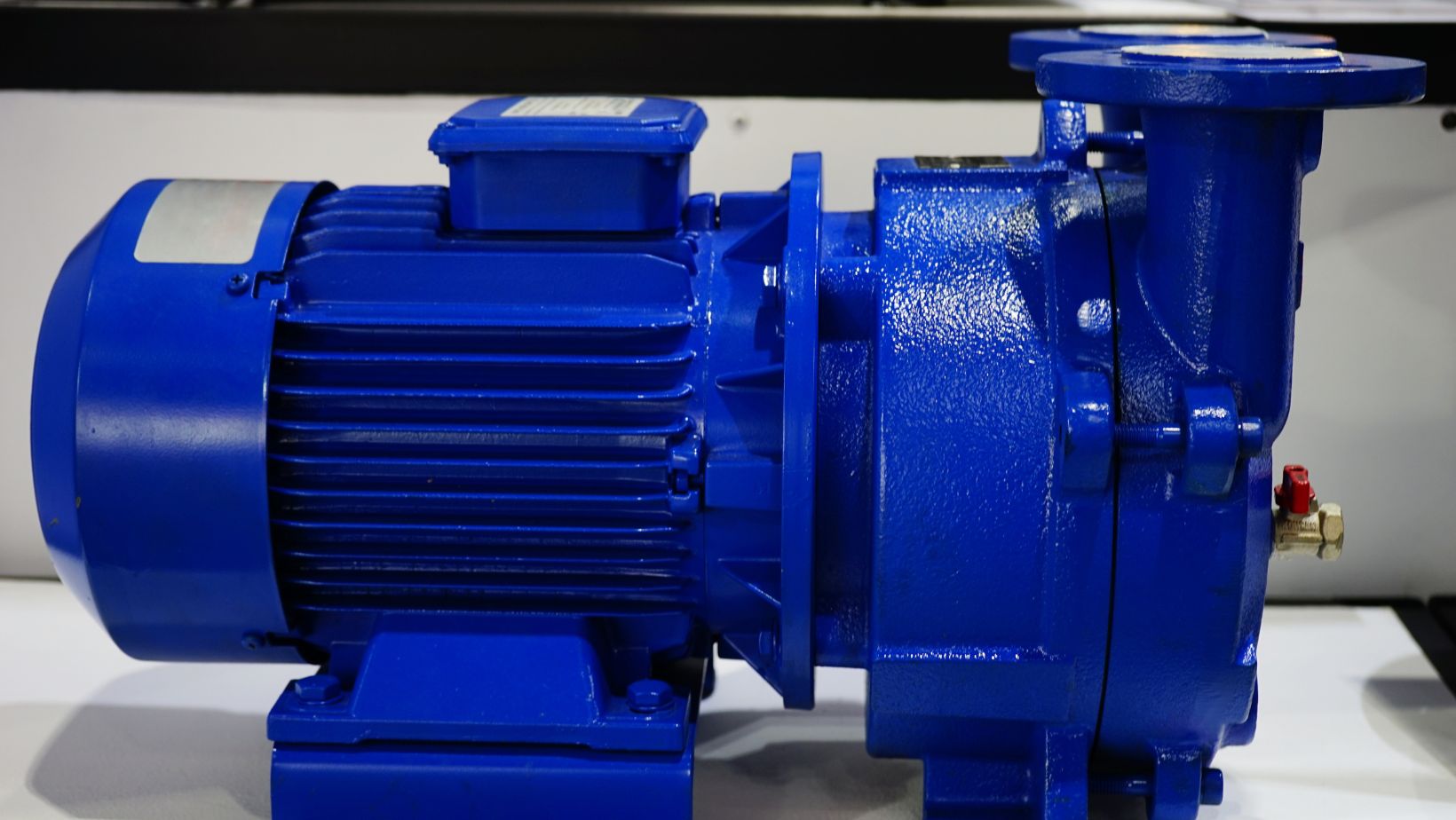

Types of Vacuum Pumps

When it comes to understanding what a vacuum pump is used for, it’s essential to delve into the different types available. Here are some common variations:

- Rotary Vane Pump: This type of vacuum pump utilises rotating vanes to create a vacuum by trapping and compressing gas molecules. It is commonly used in applications such as refrigeration, air conditioning, and automotive industries.

- Diaphragm Pump: A diaphragm pump uses a flexible membrane or diaphragm that moves back and forth to create suction and discharge pressure. This pump is often employed in laboratories, medical devices, and small-scale industrial processes due to its oil-free operation and ability to handle corrosive gases.

- Scroll Pump: The scroll pump operates on the principle of two interlocking spiral scrolls that create chambers where gas gets trapped and compressed before being expelled. Its oil-free design makes it suitable for applications like semiconductor manufacturing, analytical instruments, and pharmaceutical processing.

- Turbomolecular Pump: Designed for high-vacuum applications, the turbomolecular pump uses rapidly spinning blades to propel gas molecules towards an exhaust stage. These pumps are widely used in research facilities, particle accelerators, and other scientific experiments that require ultra-high vacuums.

- Liquid Ring Pump: In this type of vacuum pump, a liquid ring created by centrifugal force serves as the sealing element between the impeller blades. It finds application in industries such as chemical processing plants, power generation plants, and wastewater treatment facilities.

Each type of vacuum pump has its own unique characteristics and advantages depending on the specific requirements of the application at hand.

Remember that this section is part of an ongoing article about what a vacuum pump is used for; hence maintaining consistency with tone throughout will help engage readers seeking information about these various types of pumps.